Tesla’s potential as a future battery supplier for other automakers is being paved by the ongoing struggles of the company’s rivals today. This idea is becoming more and more feasible as more and more veteran automakers experience battery-related challenges in their respective electric car programs.

Building electric cars is no easy task. As evidenced by the issues plaguing the rollout of the mass-market Volkswagen ID.3, making good electric vehicles is not just a matter of stuffing an electric motor and batteries in an existing platform for an internal combustion car. Making EVs, especially good, high-performing ones like the Tesla Model 3, requires mastery of a different set of skills, such as software management and battery optimizations.

The latter is where a vast divide exists between Tesla and legacy automakers today. Tesla utilizes its own proprietary battery tech for its vehicles. The 2170 cells for its Model 3 sedan are even being produced at Giga Nevada, a massive factory that is poised to become one of the largest in the world by footprint once it’s completed. Veteran automakers, on the other hand, rely on suppliers such as LG Chem to supply their EVs’ batteries.

LG Chem supplies cells to several automakers, including Audi and Jaguar, whose e-tron and I-PACE both utilize the company’s batteries. Rivian, which uses 2170 cells for the R1T pickup and the R1S SUV, source their cells from the South Korean firm as well. More recently, even startup Lucid Motors, which is reportedly on the cusp of releasing its first vehicle, the Air, also announced that it would be sourcing cells from LG Chem. This is great for LG Chem, as it validates the quality and capabilities of its batteries, but it also does not bode well for all the companies looking to acquire adequate battery supply for their electric cars.

As it is, LG Chem appears to be having difficulties meeting the demand for its vehicles already. Shortages of cells from the battery manufacturer have reportedly become the cause for the recent halts in the Audi e-tron and the Jaguar I-PACE’s production. And this is just with premium-priced, mid-volume SUVs. When high-volume vehicles enter the market, such as the Volkswagen ID.3 (which also gets some of its cells from LG Chem), the South Korean firm will likely find it even more challenging to supply batteries to all its clients.

This supply issue could become a serious challenge to the electric car revolution. With this in mind, and with even more electric cars coming in the next few years, a need for another battery supplier emerges. This is where Tesla comes in. Tesla has been expanding its business to not just focus on building electric cars, as evidenced by the company’s energy and battery storage initiatives. Considering Tesla’s experience in building EVs, as well as the industry-leading quality of its batteries, the company may very well be poised to become one of the leading suppliers of cells for other electric car makers.

Interestingly enough, CEO Elon Musk has mentioned the possibility of Tesla serving as a supplier of batteries and powertrains to other automakers in the past. This was explained by Musk himself during the Q3 2019 earnings call. “It would be consistent with the mission of Tesla to help other car companies with electric vehicles on the battery and powertrain front, possibly on other fronts. So it’s something we’re open to. We’re definitely open to supplying batteries and powertrains and perhaps other things to other car companies,” he said.

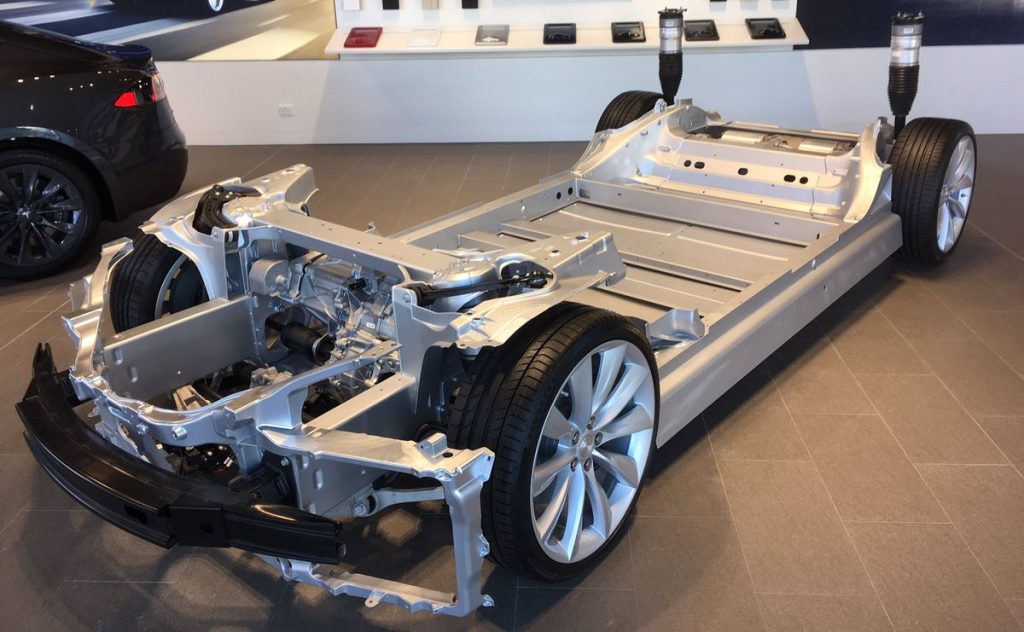

Fiat-Chrysler CEO Steve Manley also suggested the idea during a Q&A session. Speaking about the company’s electric vehicle strategy, Manley mentioned that Fiat-Chrysler would likely be purchasing key electric car components from the Silicon Valley-based company. “It would be wrong of me to say no,” Manley said, adding that batteries and drivetrains will likely be among the parts that FCA will be purchasing from Tesla. The CEO also expressed the possibility of FCA acquiring a “skateboard” platform from Tesla, which it would use for its own vehicles.

Tesla is at a point where its lead in the electric car space is undeniable. The company is also at a point where its manufacturing systems are more refined than before. Tesla may thus be reaching a stage where it is large and robust enough to support other automakers that are also adopting electric cars. As veteran carmakers transition into EVs, those who can secure battery supply from Tesla will likely be the ones that will survive what could very well be a painful and costly move towards sustainability.

<!–

–>